There are various safety measures that an organization should implement to ensure that its workers are not put to any risk of injury. Lockout/Tagout is one such procedure that is used in organizations dealing with heavy machinery and equipment.

Lockout/Tagout is a series of procedures laid down by the Occupational Safety and Health Administration under Title 29 Code of Federal Regulations (CFR) Part 1910.147. This regulation helps safeguard workers from the risks involved while dealing with servicing and maintenance of machinery and equipment. It has been estimated that Lockout/Tagout has helped prevent the loss of 120 fatalities and around 45,000 injuries every year since its inception. These figures can go up if all the organizations adhere to all rules and regulations religiously.

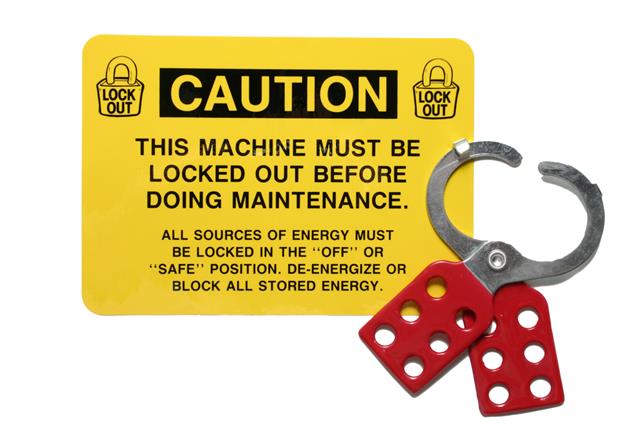

In a Lockout/Tagout program, all the power sources of a machine are locked so that these can’t be activated and then the locks are tagged so that the message is conveyed to everyone that the maintenance activities are being carried out. This ensures that nobody turns on the power supplies accidentally, which in turn reduces the risk of accidents.

Lockout/Tagout procedures are to be implemented in every industry in which servicing and maintenance of large machines is required. Before these procedures came into effect, a lot of workers used to die of injuries sustained while repairing machinery or by getting an electric shock.

Tips for Employers

It is the responsibility of the employer that the workers are well aware of all the rules and regulations regarding workplace safety. Employers also need to ensure that they have an energy control program in place which prevents the workers from the risks of hazardous energy. Some of the things that can help employers to comply with the Lockout/Tagout program are :

- The first and foremost thing that an employer is expected to do is to develop an energy control program. He can then conduct a training program so that all the workers are aware of the safety procedures

- Employers can develop a written program enlisting the procedures of Lockout/Tagout and copies can be distributed to employees.

- Once the training is completed, ensure that the employee who is entrusted with Lockout/Tagout has undergone proper training under an approved energy control program.

- Employers should also ensure that worker who has applied the Lockout/Tagout only has the authorization to remove it.

- Employers can also review the safety modes employed annually and see whether the Lockout/Tagout procedures are in accordance with any new legislation introduced.

Tips for Workers

It is the responsibility of both employers and workers that all the safety measures including Lockout/Tagout are followed so that accidents and injuries can be decreased. Here are some tips:

- If you have been entrusted with the carrying out the Lockout/Tagout program, then always ensure that you do not share your lock or keys with anyone.

- Before starting the maintenance activities, ensure that the energy is completely dissipated and the machine is safe to be used.

- Lockout/Tagout devices should be compatible with the environment in which they have to be used.

- While restarting the equipment, ensure that the all the co-workers are at a safe distance from the equipment.

Common Mistakes to be Avoided

Despite all the rules and regulations that have been laid down for the safety of workers dealing maintenance of large machines, thousand of injuries still occur due to negligence and poor implementation of Lockout/Tagout procedures. Some common mistakes while Lockout/Tagout are:

- Some experienced workers feel that stopping and restarting the equipment consumes a lot of time and effects productivity. They feel that as they have spent a lot of time dealing with machines, they can handle the situation without following the Lockout/Tagout procedures.

- In most of the instance of injuries to workers, the alibi that one gets to hear frequently is that “I didn’t know he was still in there”. There is a high possibility that workers can be negligent while adopting the safety measures and can cause injury to their fellow workers.

- Telling co-workers who are not properly trained to remove the Lockout/Tagout has led to many incidents in the past, but this practice is still common in some organizations.

- Leaving the key in the lock while applying a Lockout/Tagout is another common mistake that workers make fearing they might misplace the key.

These were some of the common mistakes that are observed while carrying out the Lockout/Tagout. Lockout/Tagout procedures shouldn’t be viewed as an unnecessary exercise as these have helped prevent many accidents in the past. Also, just agreeing to implement Lockout/Tagout doesn’t assure one that there would no longer be any workplace accidents.